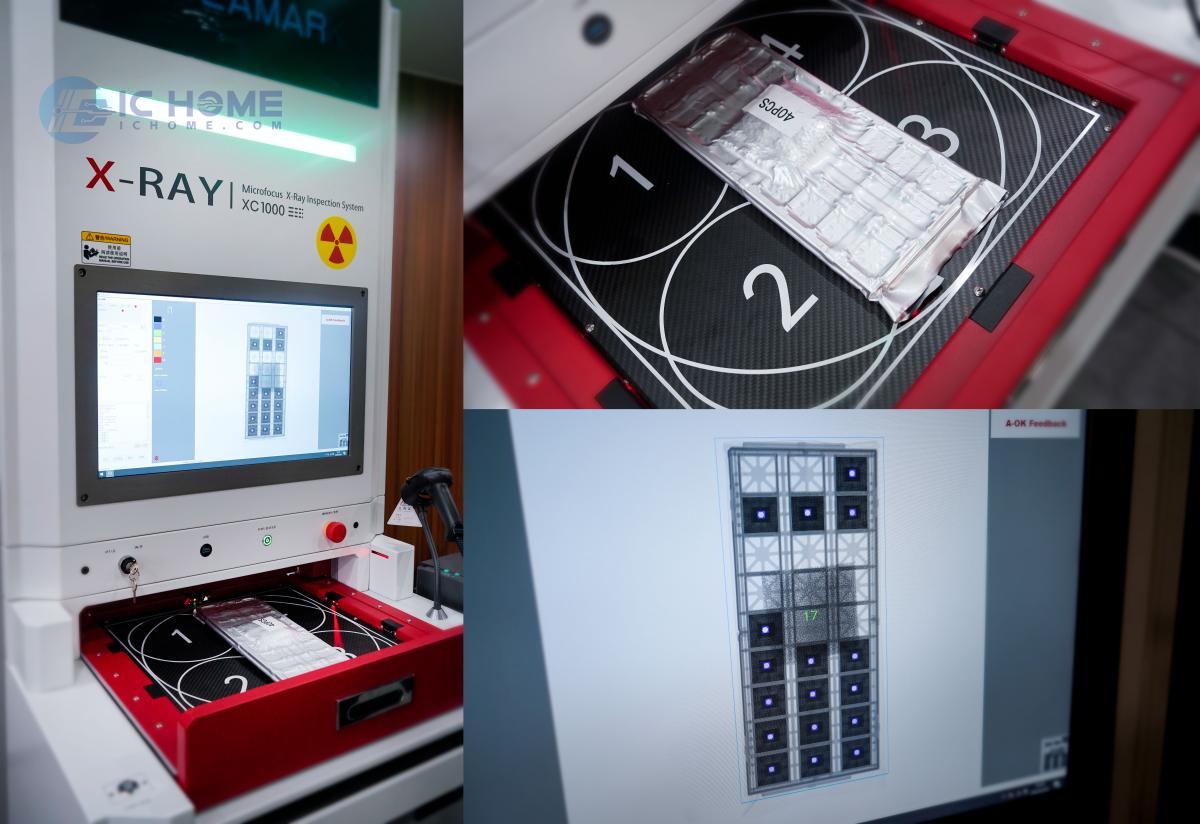

ICHOME Precision X-ray Inspection, Safeguarding Product Quality

X-ray inspection is a non-destructive testing method that utilizes low-energy X-rays to penetrate materials and reveal internal structures and defects. By capturing the variations in X-ray absorption, detailed images of the object's interior can be generated. This powerful technique allows for precise detection of flaws such as voids, cracks, inclusions, and foreign objects, ensuring product quality and reliability. When you purchase components from ichome, we also provide X-ray inspection services.

How X-ray Inspection Works

X-ray tubes emit high-energy electrons that collide with a metal target. The rapid deceleration of these electrons generates X-rays, which then pass through the material being inspected. Different materials attenuate X-rays to varying degrees based on their density and atomic composition. By measuring the intensity of the transmitted X-rays, a detailed image can be created.

Applications of X-ray Inspection

X-ray inspection finds wide application in various industries, including:

Electronics:

Inspection of integrated circuits (ICs), printed circuit boards (PCBs), and electronic assemblies

Detection of solder defects, delamination, and foreign objects

Analysis of battery components and semiconductor devices

Manufacturing:

Quality control of metal castings, welds, and composites

Detection of flaws in automotive components, aerospace parts, and medical devices

Inspection of food products for contaminants

Medical:

Diagnostic imaging of bones, teeth, and internal organs

Detection of tumors and other abnormalities

Security:

Screening of luggage and cargo for contraband

Inspection of packages for hidden objects

Benefits of X-ray Inspection

Non-destructive: Does not damage the inspected item

High resolution: Provides detailed images of internal structures

Versatility: Can inspect a wide range of materials and components

Rapid inspection: Efficient process with minimal sample preparation

Quantitative analysis: Enables measurement of defects and material properties

ICHOME's X-ray Inspection Services

At ICHOME, we offer advanced X-ray inspection services to meet the diverse needs of our clients. Our state-of-the-art equipment and experienced technicians provide:

Customized inspection solutions: Tailored to your specific requirements

High-resolution imaging: Detailed analysis of internal structures and defects

Accurate and reliable results: Adhering to industry standards

Fast turnaround time: Minimizing downtime and accelerating product development

Comprehensive reporting: Detailed reports with clear visual representations

X-ray Non-Destructive Testing (NDT) Applications in Industry and Electronics Manufacturing:

BGA inspection: Detection of voids, solder defects, and component placement issues

PCB analysis: Evaluation of circuit board quality and integrity

Metal casting inspection: Identification of porosity, inclusions, and cracks

Foreign object detection: Removal of contaminants from products

By leveraging X-ray inspection, ICHOME helps our clients ensure product quality, reduce costs, and enhance overall product reliability.

Contact us today to learn more about our X-ray inspection services and how we can assist you.

Related testing blog

Commitment to Quality: How ICHOME Ensures Component Reliability